Our covered yarn

- Home>

- Our covered yarn

It is the beginning of our company that in 1959, Ichio Asano (grandfather of the current president) started a twisting industry in Kahoku County (current Kahoku-city), which is a district of textile industries.

Since our company changed business to the field of covering yarns for manufacturers of elastic webbing of fabric in 1968, we are manufacturing covered yarns by combining yarns with different thicknesses, colors, and materials while responding precisely to your request.

Recently, the usage of covered yarn includes many things such as apparel (innerwear, outerwear), medical care, vehicles, industrial materials, and the like.

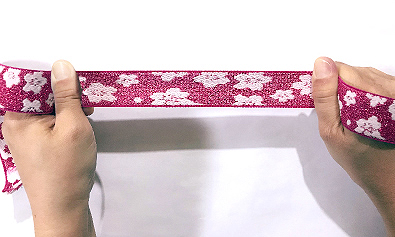

Usage examples of elastic webbing of fabric

Covered yarn is used for warp

Covered yarn is used for warp It stretches sideways

It stretches sideways Goggles

Goggles Rubber part of innerwear

Rubber part of innerwear Suspenders

Suspenders

Development of high-value-added products

Our textured composite yarns that are excellent in elasticity and maintain strong stretchability and restoring force were created by inventive research.

While our textured composite yarns (covered yarns) having excellent stretchability have already been highly valued both domestically and abroad, we will continue to focus on making product that can be boast to the world without accepting things as they are.

Production process

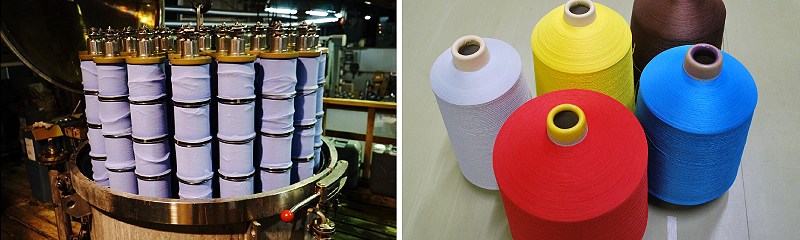

Raw yarn

Dyeing (in our subcontract factory)

In the process of dyeing, yarns obtained from textile manufacturers are dyed various colors you want.

According to the selected materials to be dyed, dyeing conditions such as pressure, temperature, and time are controlled strictly to achieve the optimal conditions and the yarns are colored.

Different materials from thin yarns to thick yarns can be dyed by chemical reaction without limiting to chemical textiles such as polyester and nylon.

Process of "bobbin winding"

In the process of "bobbin winding", dyed yarns are wound up to a spool which is referred to as a bobbin.

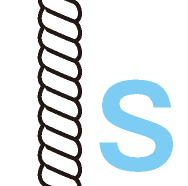

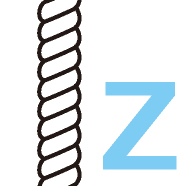

Preparation is made by applying the optimum tension so that the yarns are unwound in the right direction (Z) and the left direction (S), respectively.

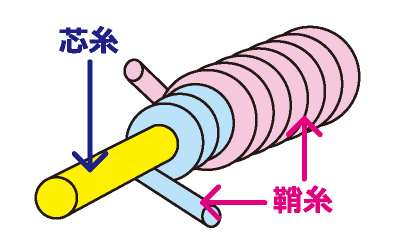

Process of making textured composite yarn (covering)

The bobbin is set into a rotating shaft referred to as a spindle.

Polyurethane elastic fibers are passed through the hole of the spindle from the downward direction, and the polyurethane elastic fibers are twisted in the right direction (Z) and the left direction (S) to the core, respectively.

This is referred to as "covering" since the yarn which was wounded quantitatively in the process of "bobbin winding" wraps the core yarn like a sheath.

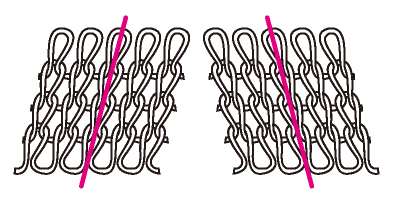

The sheath yarns are wrapped doubly in the S direction and the Z direction at the point where the core yarn is drawn.

The sheath yarns are wrapped doubly in the S direction and the Z direction at the point where the core yarn is drawn.

Clockwise rotation - right twist (S-twist)

Clockwise rotation - right twist (S-twist) Counterclockwise rotation - left twist (Z-twist)

Counterclockwise rotation - left twist (Z-twist)

When the balance of twisted yarn is bad, the knitted fabric is inclined obliquely, and the one having a square shape becomes a parallelogram.

When the balance of twisted yarn is bad, the knitted fabric is inclined obliquely, and the one having a square shape becomes a parallelogram.